IC Packaging

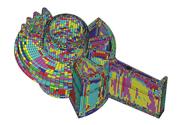

Plastic Chip Encapsulation is a molding process where chips are being capsulated with Epoxy Molding Compound (EMC) to prevent physical damage or corrosion. This process contains the interconnection between microchips and other electronics (so-called wire bonding), curing phenomenon of thermoset material, and various control management of process conditions. Due to the complexity of multiple material components, such as EMC, chip, or leadframe, and high wire density, many challenges and uncertainty have been brought to the Chip Encapsulation process. Common defects include incomplete fill, welding lines, air traps, voids, wire sweep, paddle shift, package warpage, etc.

> Parametric modeling capability enables users to build high-quality models

>Visualize filling and curing processes and predict potential molding defects

> Optimize gate and runner designs and reduce cycle time

> Visualize wire sweep and prevent wire crossing problems, such as short circuit or broken wires

> Predict paddle deflection caused by pressure drop during the mold filling process

>Predict warpage in consideration of the correlation among IC components, resins, and their properties

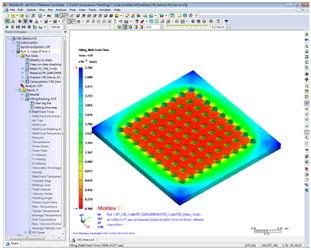

Moldex3D IC Packaging provides a complete series of molding solutions that help engineers to simulate the complex chip encapsulation process, validate mold design, and optimize process conditions.

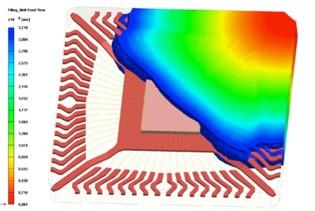

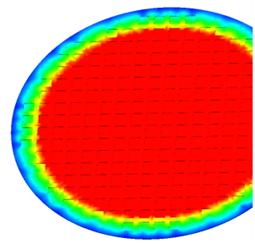

Melt front result in mold is 45% filled

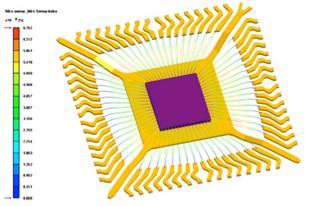

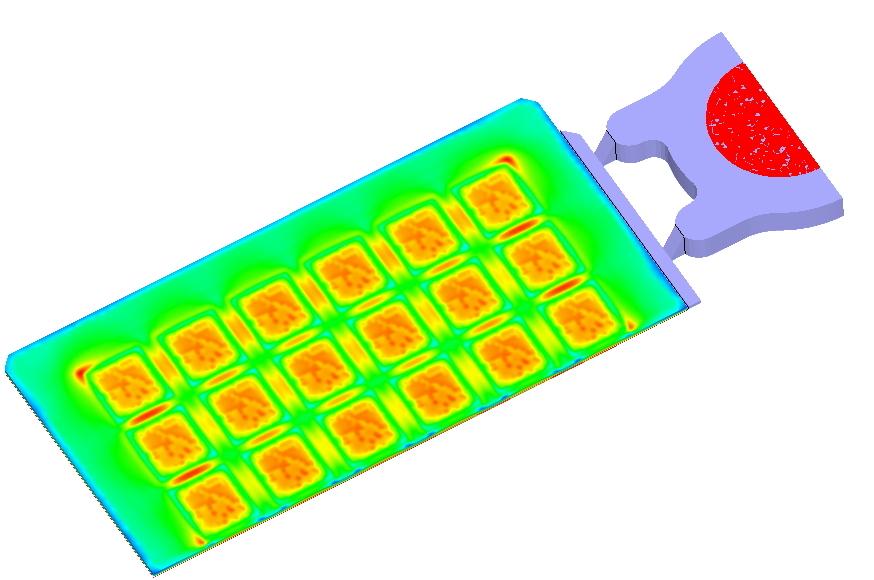

In Wire Sweep Analysis, deformed wires are compared

with original wires based on the wire sweep index

Accurate Simulation Helps Design Optimization and Cost Management

Moldex3D IC Packaging helps designers to fully analyze the chip encapsulation process from filling, curing, cooling, to advanced manufacturing demands, such as underfill encapsulation, post-molding annealing, stress distribution, or structural evaluation. Significant molding problems can be predicted and solved upfront, which helps engineers enhance chip quality and prevent potential defects more efficiently.

Support the compression molding simulation on flip chip

What’s Inside Moldex3D IC Packaging Package

MCM

Moldex3D MCM diversifies the development of plastic molded product. Its explicit analysis capabilities enable users to evaluate insert molding, overmolding and multi-shot sequential molding process, helps accurately observe interaction behaviors and minimize part warpage.

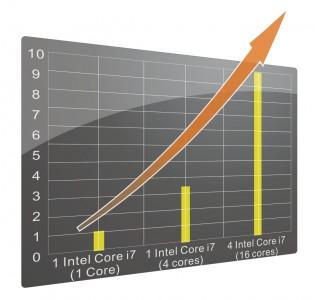

Parallel Computing

all Moldex3D 3D solvers support multi-core and multi-CPU parallel computing to greatly shorten simulation time. Parallel computing can be done locally at your desktop or remotely on a computing cluster.

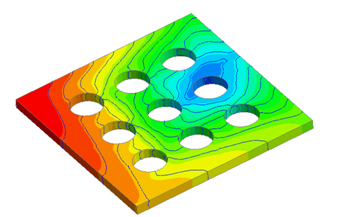

FEA Interface

provides a series of FEA Interface modules integrated with industrial leading structural software, including ABAQUS, ANSYS, LS-DYNA, Marc, Nastran, and Radioss. Users can export Fiber and Stress analysis results to calculate further structural performance.

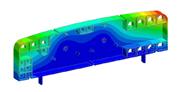

Stress

provides stress distribution for parts and part inserts. Users can set boundary conditions, such as stress or force, to evaluate the structure quality of plastics and predict potential breakage or deformation.

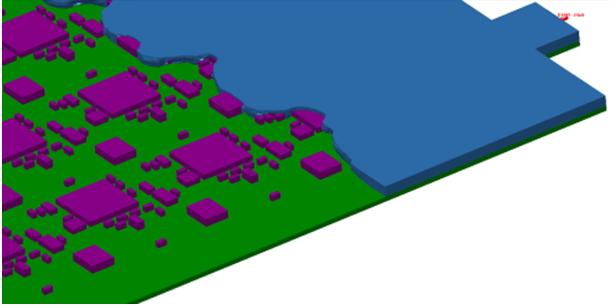

Underfill (Optional Solution Add-on)

simulates the compression molding process in which the polymer is squeezed into a preheated mold cavity. Moldex3D helps users check potential defects resulted from heat and pressure, decide appropriate materials, and optimize process conditions.

Compression Molding(Optional Solution Add-on)

simulates the compression molding process in which the polymer is squeezed into a preheated mold cavity. Moldex3D helps users check potential defects resulted from heat and pressure, decide appropriate materials, and optimize process conditions.

Customer Spotlight

Viscoelasticity (Optional Solution Add-on)

calculates viscosity and elasticity variations of plastic materials under different temperature conditions. Users can evaluate the effects on molecular orientation, residual stress, warpage, and conversion

UTAC’s Report on Molded Underfill Technology Leveraged on Moldex3D and Won Best Paper of

Session in IMAPS