Moldex3D Professional Solution Package

On top of eDesign Package, Moldex3D Professional Package offers designers tools to simulate all types of designs. Users are able to obtain product insights and properties, and further to optimize processes before physical parts are built.

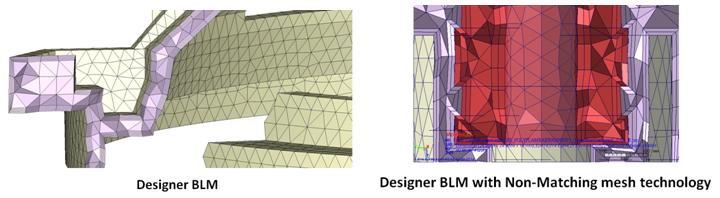

In R14.0 version, 3D coolant CFD is added into Professional Solution Package to fulfill RHCM and Conformal Cooling requirements to bring more benefits and value to users. Designer BLM module with Non-Matching mesh technology is also added into preprocessing interface to facilitate the part and mold creation and auto meshing technology enable users to work in CAD with no need for advanced CAD knowledge. The brand new Moldex3D Professional Package helps companies to design products with confidence, reduce development costs, and shorten time to market.

What's Inside Moldex3D eDesign

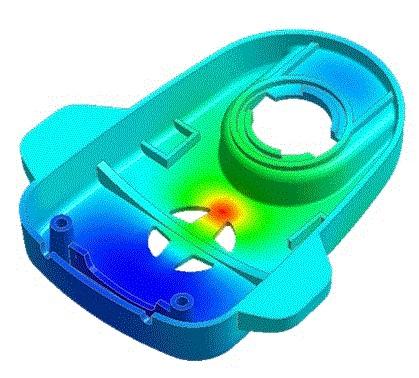

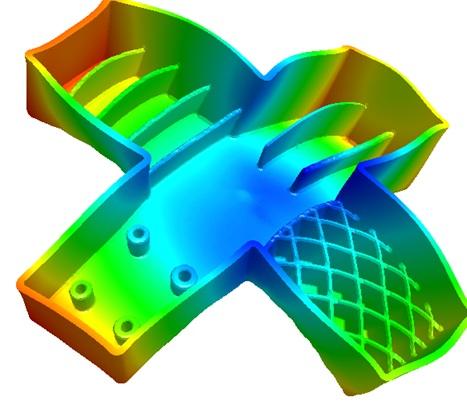

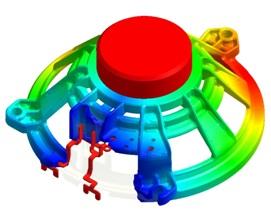

FLOW

Moldex3D Flow enables users to simulate the filling patterns of injection molding to help predict potential manufacturing problems, such as weld lines, air traps, short shots, sink marks, etc., and verify gate contribution for flow balance.

PACK

Moldex3D Pack incorporates the material compressibility (PVT changes) to fully simulate the density variation and melt flow behaviors during the packing process. It helps users precisely determine gate freeze time, efficient packing time and packing pressure, and warpage prediction to minimize high volumetric shrinkage.

COOL

Moldex3D Cool improves cooling system productivity and efficiency to optimize mold and cooling circuit designs and reduce cycle times, especially for complicated geometry parts simulation. Furthermore, the advanced transient cool feature is also supported to bring more accurate analyses for variotherm heating system, such as RHCM, and conformal cooling process simulation. Users can easily observe dynamic mold temperature and optimize cooling process

WARP

Moldex3D Warp provides a reliable analysis capability to simulate the key issues of shrinkage and warpage behaviors, further controlling the blemishes of molded products.

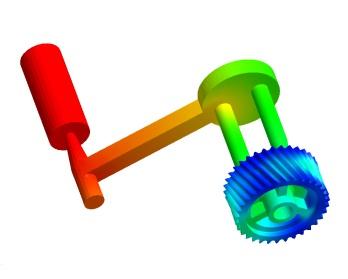

MCM

Moldex3D MCM diversifies the development of plastic molded product. Its explicit analysis capabilities enable users to evaluate insert molding, overmolding and multi-shot sequential molding process, helps accurately observe interaction behaviors and minimize part warpage.

.jpg)

RIM (Reaction Injection Molding)

Moldex3D RIM Solution is able to analyze the reactive injection molding process for thermoset materials. The typical applications include injection molding of unsaturated polyester, polyurethane, liquid silicon rubber, epoxy molding compound, etc. It is capable of simulating cavity filling and curing, part warpage, fiber orientation, multi-component process, etc.

Designer

Moldex3D Designer, designers are able to verify and optimize design changes more effectively and more flexibly.

Viewer

Moldex3D Designer, designers are able to verify and optimize design changes more effectively and more flexibly.

All Moldex3D 3D solvers support multi-core and multi-CPU parallel computing to greatly shorten simulation time. Parallel computing can be done locally at your desktop or remotely on a computing cluster.