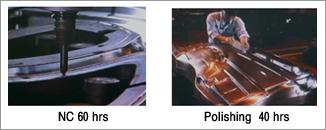

NC Machining Cost

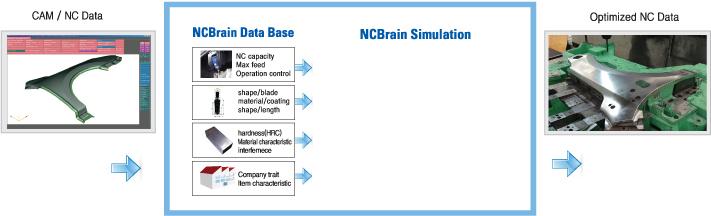

System with Data Base - Set up data base based on material, tool, equipment, and company trait.

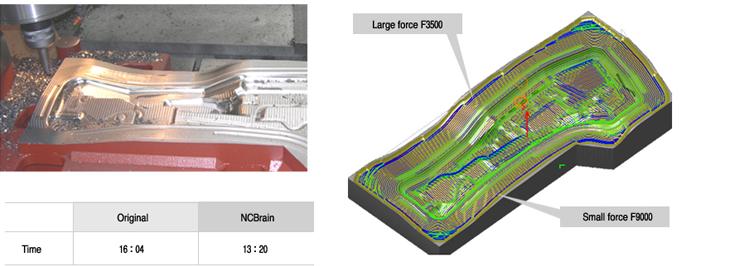

Case of Feed Control

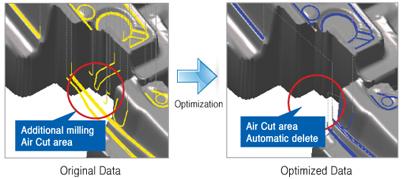

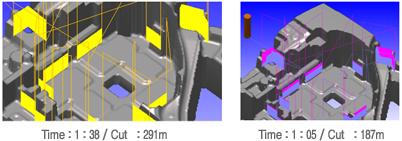

AIR CUT delete - faster milling

Structure Milling- Air Cut delete

Air Cut deleted automatically - easier CAM work

Air Cut delete for Dia-Compensatied 2D data for Structure milling

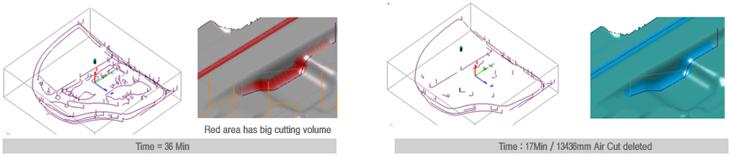

Remove very slight cutting paths

Remove paths where the cutting volume is very small in Roughing or Penciling process

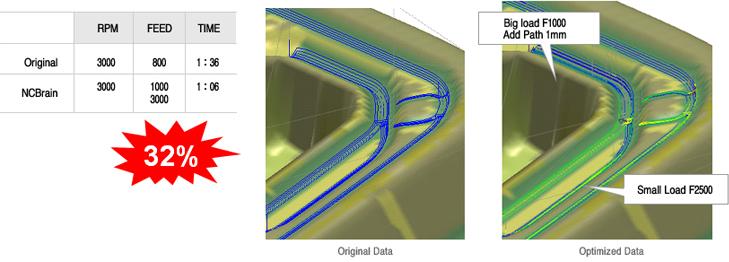

Case of path addition & Feed control

Semi-finishing, Ball30, Stock allowance 0.3 → Ball16 Stock allowance 0.3 pitch="2mm"

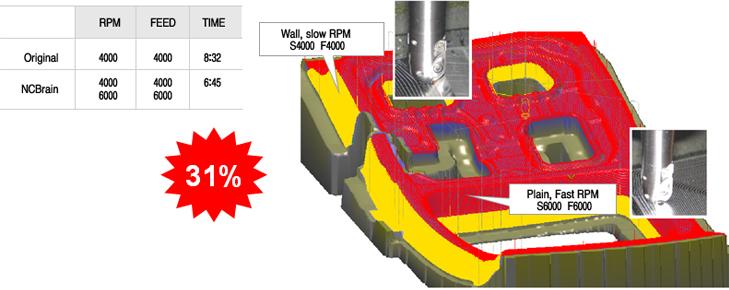

Case of RPM control

RPM control milling by refering to engage point- Ball Center or Ball Outer

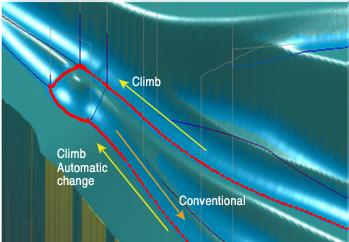

Automatic change the direction to climb cutting

Check out conventional cutting paths in Pencil process, Change to climb cutting direction

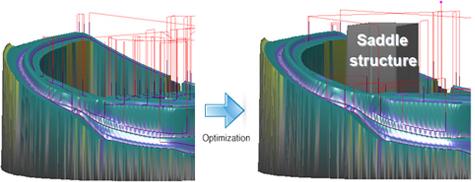

Shortest rapid move - recognize the work shape

Time cut by adjusting rapid move height

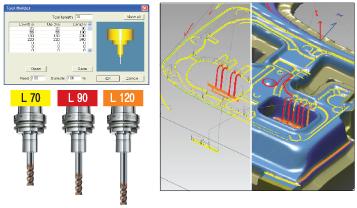

Divide NC data according to tool length itself!

Use the tool length information, devide paths along the work shape

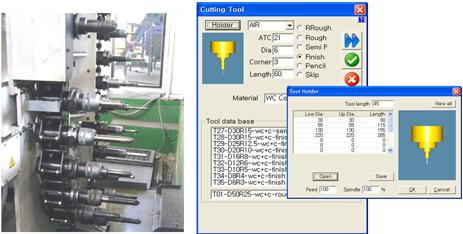

Self tool management from ATC magazine

Self ATC magazine management- tool shape, length, holder Automatically divide NC data along the tool & holder shape

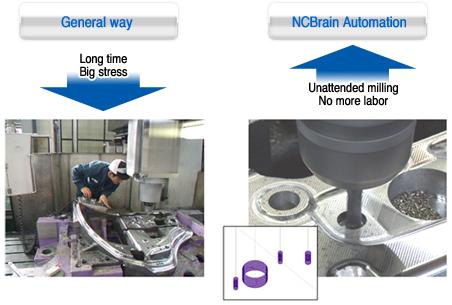

Button Die milling automation

Simply design pockets for the button dies, create NC data by "One" click

Simple and precise milling with ATC

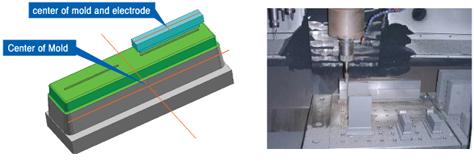

Analysis of Graphite machining

The center of mold and electrode is usually different, which causes the set up of multi coordinates and difficulties of ATC control.

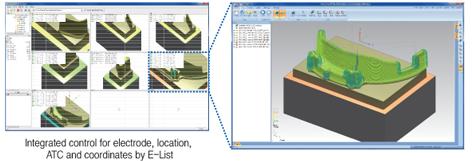

E-List makes graphite centering and can control multi graphite machining process and ATC.

E-List makes graphite centering and can control multi graphite machining process and ATC.

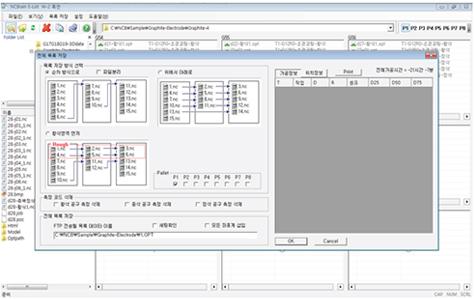

You can control milling process and ATC tools. Also, you can bind and send various NC data at a time.